Home >

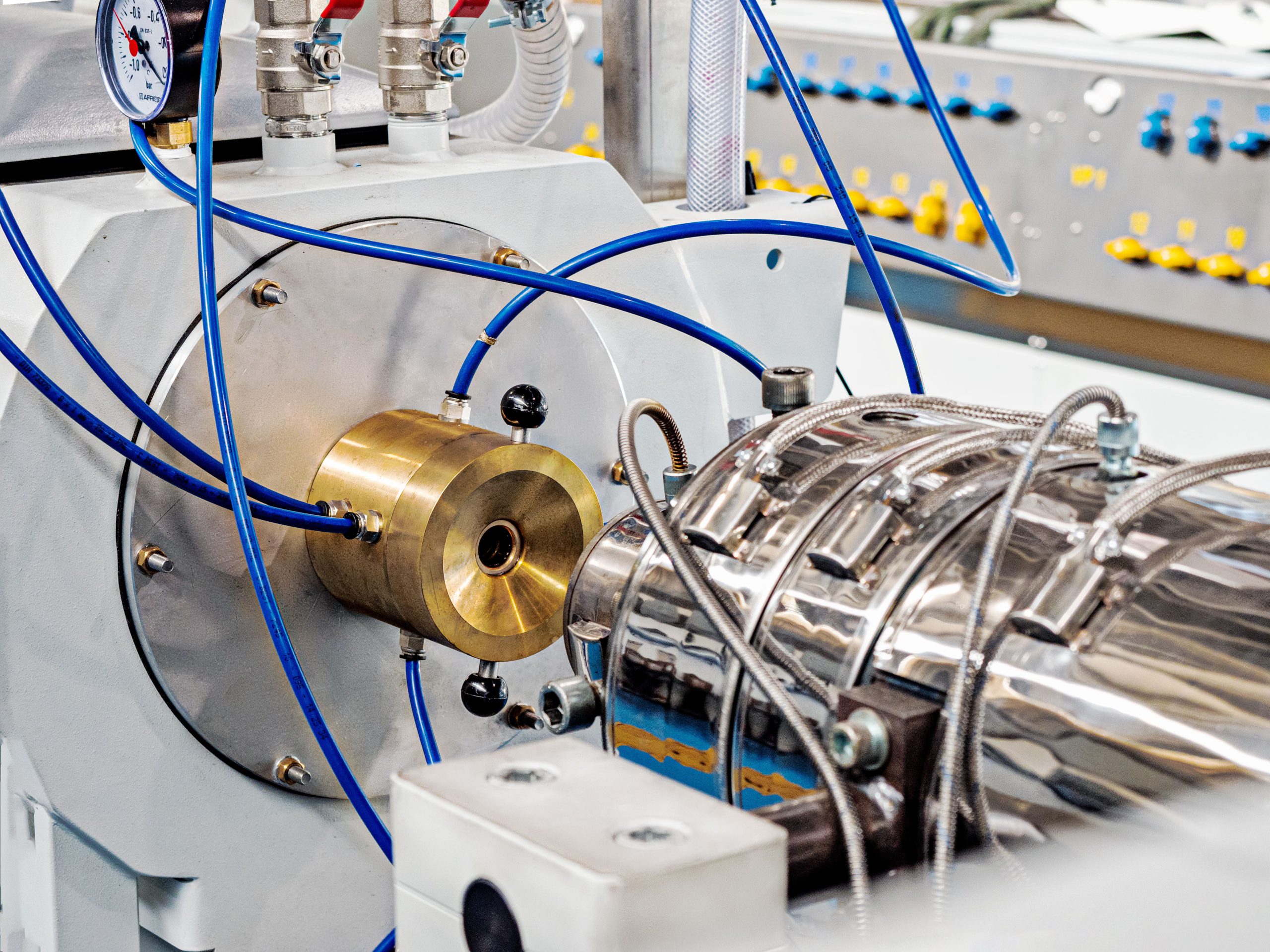

To manufacture our pipes and profiles, we have 6 extrusion lines and 3 recycling/granulation units, fed exclusively by the rigid PVC waste that we regenerate.

Our machine assets are very recent, with systematic renewal of the equipment every five years, to guarantee constant and high-quality production, by benefiting from the last technical innovations.

The plastics we recycle first undergo a filtering operation to remove any impurities, followed by a granulation phase to obtain a reformulated PVC with mechanical characteristics equivalent to a new resin.

Our two compounding lines are used for the production of our own pellets, which are used internally, but also for the direct commercial production of custom-made pellets, according to the requirements of our extruder customers.

Our current clientele is mainly composed of wholesalers and distributors for the building and public works industry, DIY chain stores, and various professional users, for many types of activities. (Wine growing, oyster farming, industry, film winding mandrels, etc.)

Our design office is able to respond very quickly to specific requests for pipes or profiles, for industrial applications or requirements that are outside building standards. (Profiles, dimensions, thicknesses or specific colors, etc.)